- Experienced East Tennessee workforce is talented and dedicated with over 650 years of combined experience in the log home/timber frame home business.

- In business since 1971 building homes for over 5000 customers nationwide.

- Managing a sawmill allows for tremendous flexibility with timber sizes and lengths and exceptional quality control. Long lengths up to 40 feet and/or diameters up to 24 inches available.

- All timbers are graded and stamped in accordance with Timber Products Inspection, Inc. which ensures our clients of the best quality material available, and the grade matches the engineering requirements.

- In 2016, we’ve managed (20) unique timber specifications including; Eastern White Pine, Yellow Pine, Boxed Heart Douglas Fir, Free of Heart Center (FOHC) Doug Fir, Coastal Western Hemlock, Hem-Fir, Cypress, White Oak, Red Oak, Antique Oak, Antique Fir, Antique Long Leaf Yellow Pine, Glulam Yellow Pine, Glulam Doug Fir, Eastern Red Cedar, Western Red Cedar, Alaskan Yellow Cedar, Borate Treated White Pine, Borate Treated Yellow Pine and IPE Decking.

- When steel exposed or hidden steel plates are required, we manage and include the steel specifications to match up with the precut timber joinery.

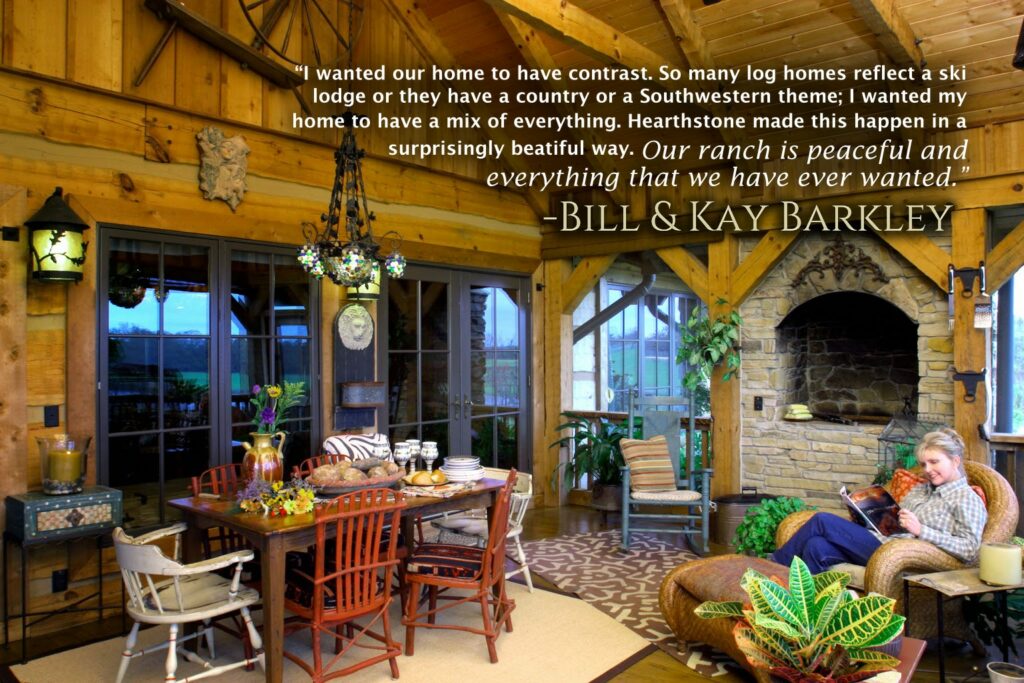

- Multiple squared and dovetailed log wall profiles including:

- 6×12 Traditional system with Half or European dovetail corners.

- 6×14 TimberWright® system with hand carved, natural look contour in the chinking space. Half, European or V-Notch corner options.

- 6″ and 8″ thick random-stacked log with 8″, 10″ and 12″ Traditional, or 10″, 12″ and 14″ larger scale Timberwright alternative.

- 6″ and 8″ thick hand-crafted Bob Timberlake system with large logs ranging from 12 to 23 inches wide with naturally contoured edges

- 8×16 full compound dovetail with 3 inch chink space.

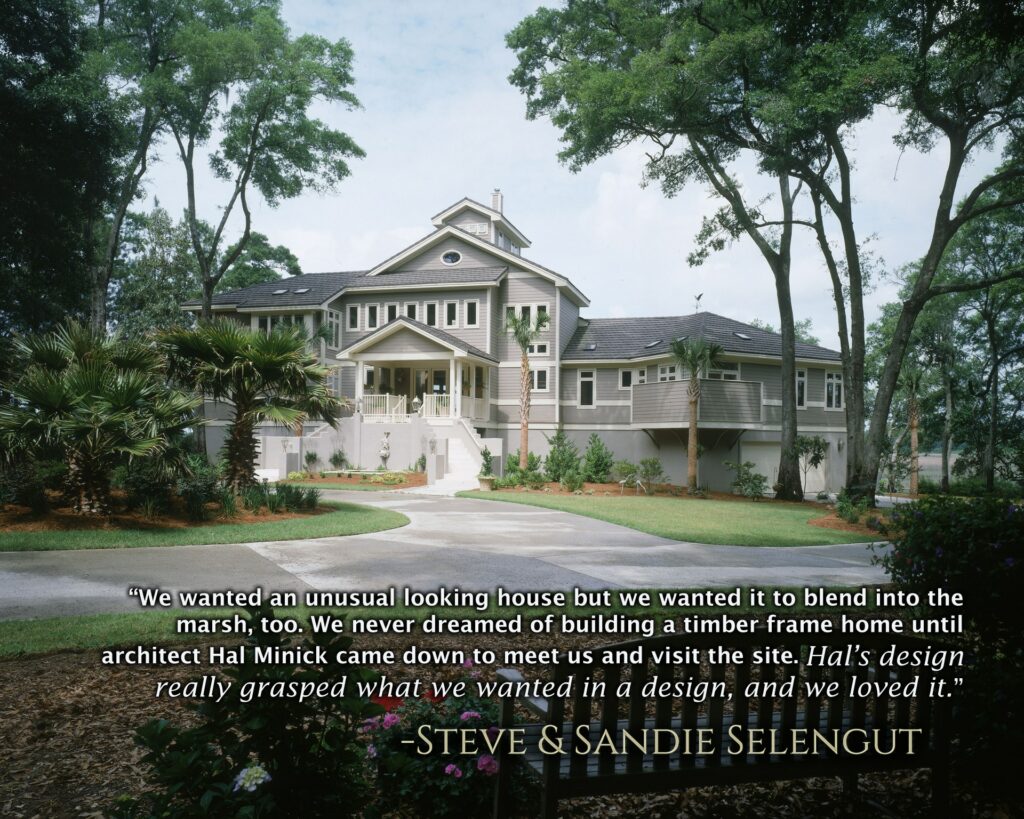

- Architectural design staff features over 150 years of experience designing and building log and timber frame homes.

- Standard blueprint services include cross sections, floor plans, foundation plans, four elevations, and additional details for most permit and construction requirements.

- CAD solid modeling software offers the latest in 3D modeling so complex designs can be viewed in three dimensions prior to manufacturing.

- SBCCI code approved log system engineered for 110 mph (176 km/hr) wind load and seismic zone 3. Higher wind and seismic zone engineering available. Download PDF

- Timber frame system engineered and manufactured in conformance to the National Design Specifications for Wood Construction and Supplement 1991 edition.

- Model Energy Code approved building systems.

- International Residential Code (IRC) approved building systems.

- Japanese National Building Code approved building systems.

- Engineering review and stamps available in most all states.

- Construction manual(s) to assist the builder with the finish details of construction.

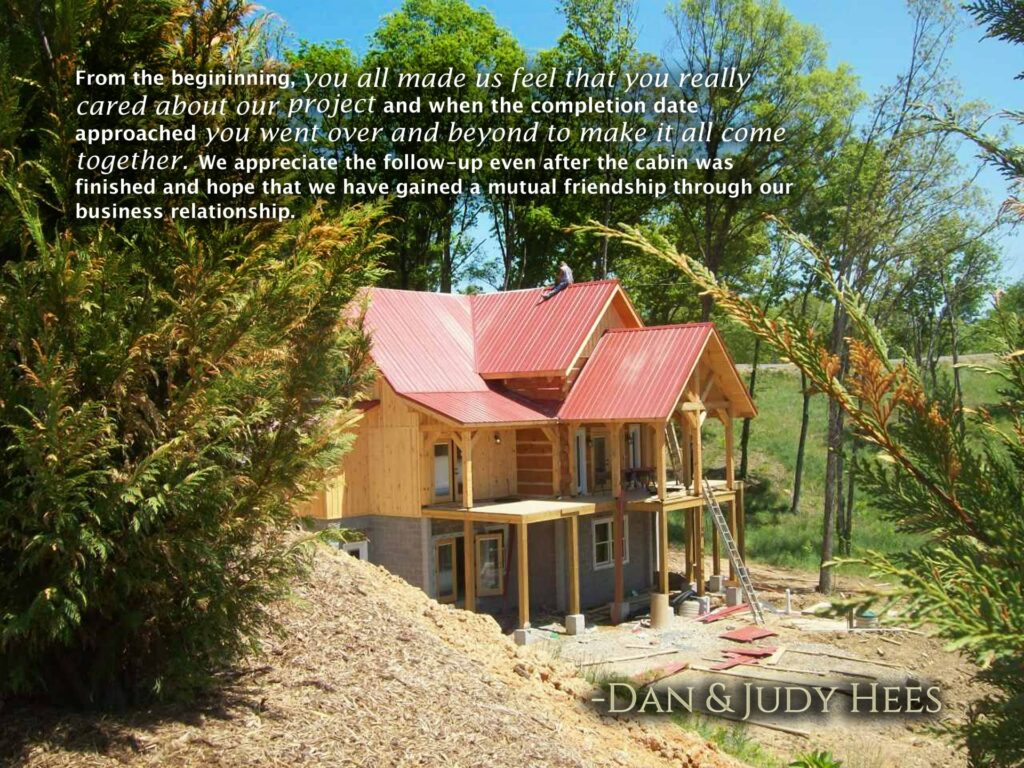

- Cost plus regional turnkey services managed by our sister company, Mountain Timber Structures, LLC.

- Fixed fee nationwide installation services provided MTS.

- Expanded national construction services including chinking, staining, metal roofing, etc..

- Experienced Technicians available worldwide to travel and work alongside your own builder or crew during any phase of construction.

- Package and turnkey estimating system(s) provide clear and concise specifications and detailed Proposals.

- Confirmation schedule adjusts for change orders and provides customers with exact costs and specifications prior to scheduling a firm delivery date.

- Company owned trucks and employee drivers with over 80 years combined experience delivering materials to the most remote of job sites.

- Each load is securely banded, wrapped and/or tarped for protection during shipment.

- Experienced export service available using vendor from Knoxville, TN.

- Delivery of commonly available construction materials managed from locally available sources to avoid unnecessary loads of freight from East Tennessee.

- Off-loading and delivery of materials to site included with installation service.

- Logs rest on foundation wall/PT sill in most instances. This provides a more aesthetically pleasing transition from foundation to log wall and reduces cost associated with covering up the sub-floor and accessing electrical wiring.

- 8′-10″ First floor ceiling heights standard.

- Precut rough openings per plan as approved by client.

- Pre-drilled wiring holes and easy electrical access in all log system(s) will reduce finishing labor cost and allow for changes after system is erected.

- Shrinkage and settling engineered into every log system including:

- Window, door and fireplace openings designed with adjustable jamb system.

- Interior and exterior support posts designed with adjustable jacks to allow for settlement of walls.

- Throughbolts, nuts, washers and compression springs used in log construction to tighten walls during erection and long after settling begins.

- Chink space rigid spline material and load bearing blocks designed to keep system air tight as log walls shrink and settle.

- Porch material precut with birds mouth rafters and mortise and tenon joinery.

- Gable dormer heavy timber valley and jack rafters precut with precision.

- Hip roof and valley rafters designed and precut with precision.

- Shed dormer walls pre-built in factory.

- Heavy timber log stair system and banister posts provided.

- Heavy timber fireplace mantels and brackets provided.

- Chink space cavity is insulated up to R-24 for increased efficiency.

- Chink space construction allows for future access and ease of replacement/repair if necessary many years down the road.

- Chinking material easily maintained and available in seven colors.

- Standard built up roof system provides R-38 or R-49 insulation for increased efficiency and lower utility bills.

- Premium grade “V-edged” 2×6 spruce tongue and groove provided for second floor systems, main roof decking and porch roofs. The beauty, color, tightness of knots and ease of installation all complement the heavy timber construction.

- Specialty and common materials designed to complement system.

- Multiple timber finishes available including:

- Hand Hewn

- Planed

- Planed and Chamfered

- Distressed

- WeatherAgedTM.

- Sales professionally serviced by experienced staff and extensive network of Distributors nationwide.

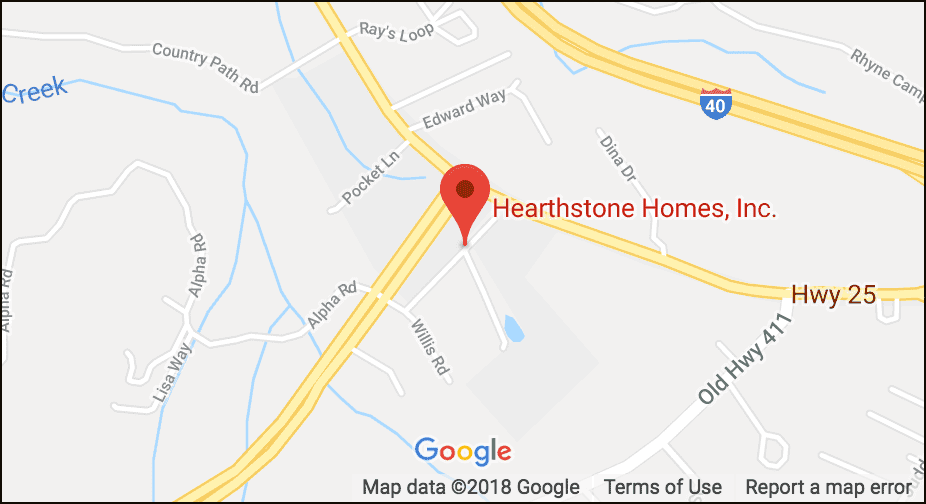

- Newport, TN factory tours encouraged with customers, architects and builders to define options and review products and services.

- Money back guarantee since 1987 unmatched by anyone in the world.

- Lifetime structural warranty.